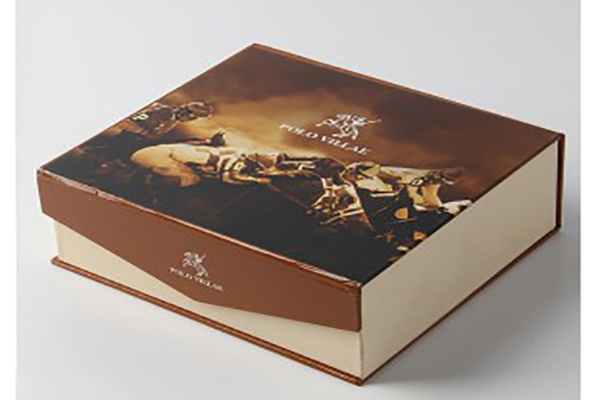

Rongli Printing provides high-quality All English packaging color box in Shanghai with state-of-the-art multi-process printing and expert craftsmanship. Supporting hot foil, spot UV, embossing, and custom shapes on food-grade materials, we offer luxury solutions. Low MOQ, free proofing, transparent costs, and efficient rush service for diverse brand applications.

Based in Shanghai, we specialize in All English packaging color box, offering a complete one-stop service from design and free proofing to mass production. Equipped with German Heidelberg presses and Japanese premium inks, we combine 6+ processes like hot stamping, spot UV, embossing, and debossing—delivering vibrant colors, sturdy structures, and luxurious feel for cosmetics, food, gift, and pharmaceutical brands.

| Service Capability | Industry Standard | Our Performance |

|---|---|---|

| Processes per Box | 3-4 processes | 6+ complex processes combined |

| Proofing Speed | 3-5 days | Free digital proof same day |

| End-to-End Support | Segmented handling | Dedicated one-stop manager |

We provide over 15 premium materials including matte white card, glossy art paper, metallic foil card, textured specialty papers, and eco-friendly kraft options. Each material is carefully sourced for consistent quality and perfect printability, enabling stunning visual and tactile effects for luxury brand packaging.

| Material Type | Standard Choices | Our Selection |

|---|---|---|

| Basic Card Stock | White & greyboard only | Matte, gloss, and coated variants |

| Metallic & Foil Papers | Limited colors | Gold, silver, rose gold, holographic |

| Textured Specialty Papers | Rarely available | Linen, pearl, embossed textures |

We set the industry’s lowest entry barrier with a minimum order quantity of just 100 pieces, while delivering the same premium materials, processes, and quality control as large runs. This enables emerging brands, e-commerce sellers, and limited-edition launches to access high-end packaging without excessive upfront investment.

| Order Quantity | Standard Requirement | Our Policy |

|---|---|---|

| Minimum Order | 500-1000 pieces | 100 pieces only |

| Quality Consistency | Reduced for small runs | Identical to large production |

| Setup/Die Charge for Low MOQ | Full charge applied | No die fee for 100+ pcs |

Our optimized production workflow and multiple parallel lines enable standard color box orders to be completed and shipped within just 7-10 working days from artwork approval. This reliable timeline supports efficient inventory planning and rapid market response for seasonal collections and regular product launches.

| Lead Time Category | Industry Standard | Our Timeline |

|---|---|---|

| Standard Production Cycle | 12-18 days | 7-10 days guaranteed |

| Artwork to Proof Approval | 3-5 days | Same day digital proof |

| Final Delivery Consistency | Variable | Fixed 7-10 day window |

Personalized packaging—variable data printing, individual names, or custom messages—is fully available starting at 100 pieces. Perfect for corporate gifting, influencer collaborations, or direct-to-consumer brands wanting to create memorable, individualized unboxing experiences.

| Personalization Option | Standard Minimum | Our Minimum |

|---|---|---|

| Variable Data Printing | 1000+ pieces | Available from 100 pieces |

| Individual Customization | Bulk only | Name/message per box |

| Setup for Personalization | High cost | Digital – low impact |

Proofs and final products are evaluated under D50 daylight, store lighting, and warm LED conditions to ensure colors appear consistent across different retail environments. This multi-light assessment prevents unpleasant surprises when packaging reaches shelves.

| Lighting Evaluation | Standard Check | Our Check |

|---|---|---|

| Viewing Conditions | Single light source | D50 + store + LED |

| Metamerism Control | Basic | Strict metamerism testing |

| Retail Appearance Prediction | Limited | Multi-environment verified |

We routinely combine 6+ processes—including printing, foil, UV, embossing, debossing, and lamination—on a single box with perfect registration. This integrated approach creates sophisticated, multi-dimensional packaging that stands out in competitive retail environments.

| Integration Level | Standard Limit | Our Limit |

|---|---|---|

| Processes Combined | 2-3 maximum | 6+ processes integrated |

| Registration Between Processes | Visible offset | Perfect alignment |

| Production Efficiency | Multiple passes | Optimized inline workflow |

Custom-designed internal cushioning systems using foam, card partitions, or molded pulp protect fragile items from shock and vibration. Each solution is tailored to your product dimensions for maximum security and minimal movement during transit.

| Cushioning Type | Standard Protection | Our Protection |

|---|---|---|

| Foam Density & Fit | Loose generic foam | Custom-cut high-density |

| Card Partition Strength | Basic dividers | Reinforced interlocking |

| Shock Absorption | Moderate | Multi-layer impact zones |

Through long-term partnerships with leading paper mills and strategic inventory management, we ensure consistent material availability and price stability even during market fluctuations. Brands benefit from reliable production scheduling without unexpected delays or cost increases.

| Supply Aspect | Standard Situation | Our Situation |

|---|---|---|

| Material Availability | Subject to shortages | Strategic stock guaranteed |

| Price Fluctuation Protection | Passed to client | Locked pricing available |

| Lead Time for Special Materials | 4-8 weeks | In-stock premium options |

Each SKU can receive its own unique labeling, barcoding, or packing instructions without additional setup time. This enables direct-to-retail or direct-to-consumer fulfillment with variant-specific packaging requirements.

| Packing Customization | Standard Approach | Our Approach |

|---|---|---|

| Per-SKU Labeling | Uniform only | Unique labels per variant |

| Barcode Integration | Single code | Individual SKU barcodes |

| Packing Instructions | Standard method | Custom per SKU |

Our Kaizen-inspired continuous improvement program tracks quality metrics, conducts regular audits, and implements employee suggestions. This ongoing evolution has driven steady improvement in yield rates and customer satisfaction scores year over year.

| Improvement Metric | Standard Progress | Our Progress |

|---|---|---|

| Annual Yield Improvement | 1-2% gain | Consistent 3-5% gains |

| Audit Frequency | Annual external | Monthly internal + quarterly external |

| Employee Suggestions Implemented | Low adoption | High implementation rate |

We create food-safe, elegant packaging for artisanal chocolates, teas, and specialty foods with inner trays, window patches, and gold foil detailing. These designs protect delicate contents while presenting products as high-end gifts that command premium pricing.

| Food Application | Standard Box | Our Box |

|---|---|---|

| Food-Grade Compliance | Basic certification | Full low-migration inks |

| Product Visibility | No window | Crystal-clear window patching |

| Gift Appeal | Plain finish | Ribbon & foil luxury details |

Customers frequently highlight our collaborative style—working as an extension of their team rather than just a supplier. From design consultation to production optimization, this partnership mindset delivers better results and stronger relationships.

| Partnership Aspect | Standard Relationship | Client Feedback |

|---|---|---|

| Team Collaboration | Transactional | "True partner mentality" |

| Design Input | Limited advice | "Valuable expertise shared" |

| Problem Solving | Reactive | "Proactive solutions" |

We explain accepted payment methods, deposit requirements, balance timing, currency options, and invoice details. Clear terms help international and domestic clients complete transactions smoothly and avoid delays in production start.

| Payment Aspect | Standard Term | Our Term |

|---|---|---|

| Deposit Requirement | 50% upfront | Flexible 30-50% |

| Accepted Methods | Bank transfer only | Multiple including PayPal |

| Currency Options | Single currency | USD, EUR, CNY supported |

Add premium touches like custom foam inserts, velvet pouches, magnetic gift boxes, and branded thank-you notes to create memorable unboxing moments. These enhancements turn standard packaging into luxurious brand experiences that customers love to share.

| Unboxing Element | Standard Inclusion | Our Inclusion |

|---|---|---|

| Custom Foam Insert | Basic shape | Precision luxury fit |

| Velvet Pouch | Separate purchase | Branded options available |

| Thank-You Note | Generic card | Premium printed insert |