Service Hotline:181-0186-9996

email:chengxunys@163.com

上一张

下一张

Ideal China Pictures of knife packaging boxes companies for low-volume runs in 2026 – Top 10 guide! Scored from 2025 short-run data on MOQ thresholds, digital viability, personalization speed, and unit economics. Profiles detail flexible policies, prototype examples, and startup client journeys. Comparison tables break down thresholds and scaling costs. Avoid low-volume traps (excessive plate charges, long queues) with targeted advice. Recommendations for testing vs. limited releases.

Shanghai Rongli Printing Factory Company Address: No. 30, Lane 2, Suide Road, Putuo District, Shanghai Tel: 18930086608

Shanghai Chengxun Printing Company Address: 1-3 Floors, Building 7, Lane 697, Lingshi Road, Zhabei District, Shanghai (Factory) Tel: 18101869996

Company address: 4th floor, No. 45 Shuifeng Road, Yangpu District, Shanghai

Company address: Jiaxing Asia-Pacific Science and Technology Industrial Park, Nanhu District, Jiaxing City, Zhejiang Province

Company address: Longchi Road, Tongcheng Economic Development Zone, Anhui Province

Company address: 22nd floor, Building A, Jinsheng Fortune Plaza, Ma'anshan Community, Shajing Street, Bao'an District, Shenzhen

Company address: No. 5 Hengsheng Road, Xiaoshan Economic Development Zone, Hangzhou City, Zhejiang Province

Company address: No. 125, Changli Road, Huangtang Town, Danyang City

Company address: No. 1668, Butang Middle Road, Wuxian Town, Tong'an District, Xiamen City

Company address: No. 588, Nanyang West Road, Jinshan District, Shanghai

Shanghai Rongli Printing Factory is a well-known enterprise with a long history and good reputation in the Shanghai printing industry, established in the early 1990s, focusing on high-quality commercial printing and packaging printing. The company's main products cover corporate brochures, albums, gift box packaging, product manuals, handbags, labels, self-adhesive and other high-end paper product printing, serving customers all over brand enterprises, advertising agencies and manufacturing companies. Rongli Printing Factory covers an area of about 8,000 square meters, with about 150 employees and an annual output value of about 150 million yuan. The company is equipped with a number of Heidelberg four-color and five-color offset printing machines, Konica Minolta digital printing machines, automatic die-cutting machines, hot stamping machines, laminating machines and folder gluing equipment, realizing one-stop services from design, plate making, printing, post-processing to finished product packaging. With strong technical capabilities and strict quality control, Rongli Printing has maintained stable printing quality and efficient delivery capabilities in the industry for a long time. Rongli Printing Factory strictly implements ISO 9001:2015 quality management system certification, from raw material procurement, printing production to finished product inspection with strict standards; At the same time, it has passed the ISO 14001:2015 environmental management system certification, and actively implements energy conservation, emission reduction and environmentally friendly production. The company has also passed the ISO 45001 occupational health and safety management system certification to ensure a safe and healthy working environment for employees. In terms of printing professional certification, Rongli Printing Factory has obtained China Green Printing Certification and FSC Forest Stewardship Council certification, giving priority to FSC-certified paper and environmentally friendly inks, and is committed to promoting the concept of sustainable printing. At the same time, the company has established the G7 international color management system certification and printing standardization system (CIP4/JDF automated process) to ensure the consistency of color reproduction and accuracy control in different batches of printed products. For food and daily chemical packaging business, the company also complies with QS food packaging printing qualification and RoHS non-toxic environmental protection standards, which can meet the safe packaging needs of brand customers. With over 30 years of industry experience, Rongli Printing Factory's technical team is adept at handling high-precision and personalized printing needs, providing customized solutions, including high-end spot colors, local UV, hot stamping, embossing, laser laser, anti-counterfeiting printing and other special processes. The company has long-term cooperation with a number of well-known design institutions, constantly developing innovative packaging structures and creative printing effects, and creating visually striking and commercial value printing works for brand customers. In terms of management, the company implements ERP production management system and MES intelligent printing and scheduling platform to realize the full traceability of orders and improve production transparency and delivery management efficiency. Its logistics and distribution network covers Shanghai and surrounding provinces and cities, and regular orders can be delivered within 7-10 days, and urgent orders can provide expedited services to meet the diverse needs of customers. Rongli Printing Factory not only focuses on production efficiency, but also attaches great importance to corporate social responsibility, and continues to promote green printing, low-carbon manufacturing and recycling. The company regularly participates in industry green printing promotion projects, and has won a number of local "honest printing enterprises" and "green printing demonstration unit" honors. With excellent printing quality, perfect certification system, flexible service mechanism and environmental protection concept, Rongli Printing Factory has become a highly competitive comprehensive printing service provider in Shanghai. Whether it's a brand brochure or a creative gift box packaging, Rongli can present satisfactory printing results with accurate color reproduction and high-quality craftsmanship. Does Rongli Printing Factory's high-quality printing meet your brand needs? Is its customization service flexible enough? Do eco-friendly printing measures reassure you? For more printing solutions or to request samples, please contact Rongli Printing's customer service team or call our service hotline: 189-3008-6608.

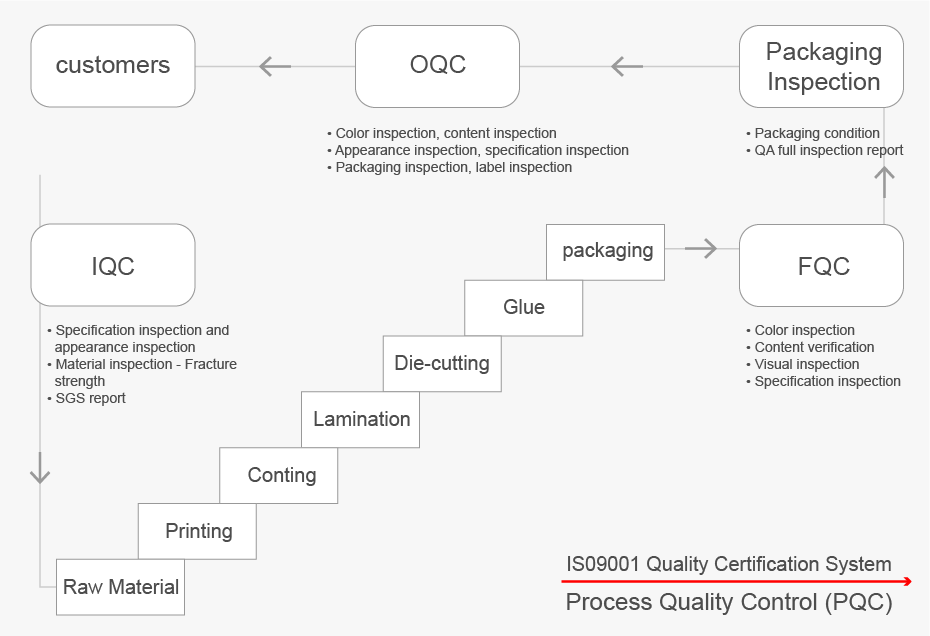

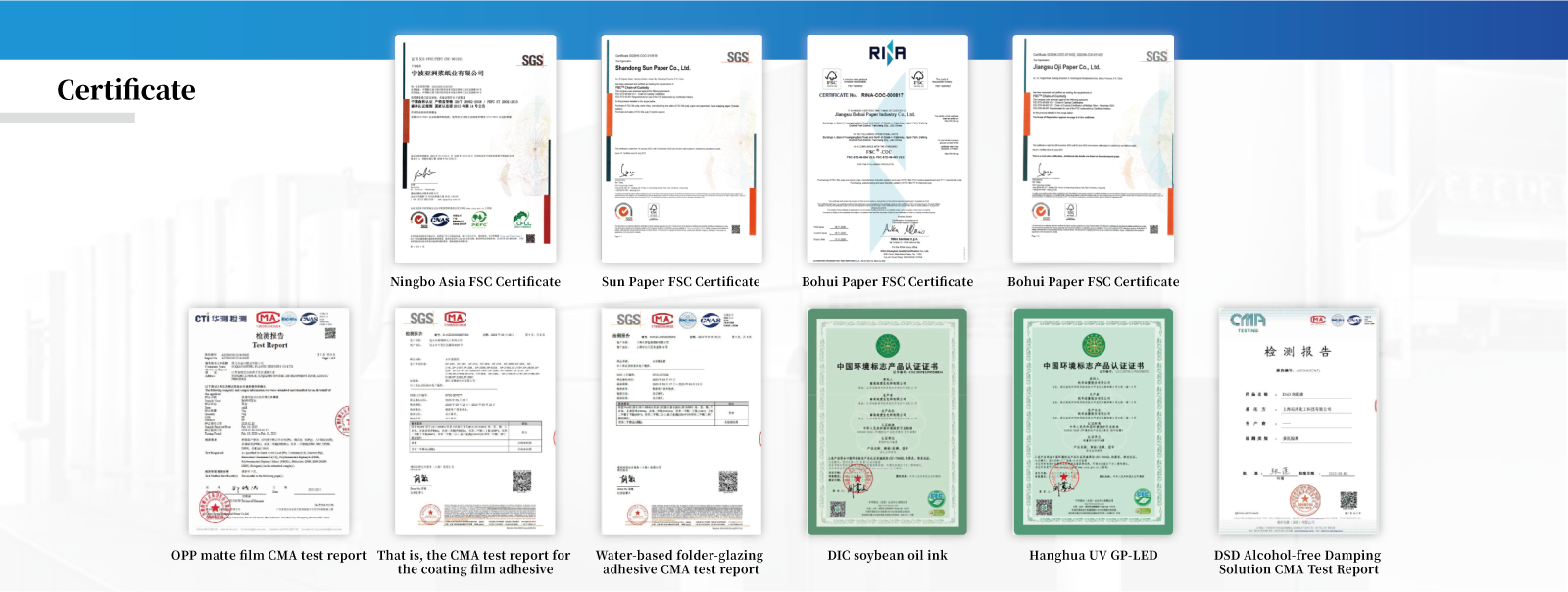

Shanghai Chengxun Printing Co., Ltd. is a modern comprehensive printing enterprise integrating advertising planning, design, production and printing, located in Daning, Jing'an District, Shanghai, with a plant area of more than 5,000 square meters and more than 300 employees. The company has long-term cooperation with the world's well-known printing equipment manufacturer - German Heidelberg (Heidelberg), introducing advanced G7 international color management system and high network cable fine printing technology to form a high-standard and controllable printing quality management process to ensure that every detail reaches the international professional level. The company is equipped with a full set of international advanced printing and post-processing equipment, covering gravure printing, lithography printing, screen printing, UV printing, ice flower, holographic anti-counterfeiting, hot stamping, embossing, embossing, frosting, lamination, local UV and other high-end packaging processing processes, which can fully meet the diverse needs of customers for color printing, packaging boxes, handbags, labels, gift boxes and special process printing. Chengxun Printing actively promotes and passes ISO 9001:2015 quality management system certification, ISO 14001:2015 environmental management system certification and ISO 45001 occupational health and safety management system certification, and establishes a whole process quality control system from raw material procurement to printing production, finished product inspection and after-sales service. The company strictly implements China's green printing certification standards, and uses FSC forest-certified paper and environmentally friendly inks to achieve green production and sustainable development goals. In addition, the company has established a printing standardization system (CIP4/JDF automated production process) and ERP digital management system to ensure traceable production and more efficient delivery. Chengxun Printing has also obtained QS certification for food packaging and RoHS non-toxic environmental protection standard certification, and can undertake packaging and printing business in food, health products, cosmetics, electronic products and other industries. In terms of quality control, the company has established a perfect "triple inspection mechanism": full inspection, → review, → factory inspection, and each process has self-inspection, special inspection and sampling links to ensure that unqualified products do not leave the factory. Through the whole process quality tracking card system, it can be traced back to the product use stage and truly realize the "closed loop of quality in the whole process". Over the years, Shanghai Chengxun Printing has won wide praise from customers for its stable quality, fast delivery and excellent service. All employees adhere to the craftsman spirit of "excellence and continuous improvement", adhere to the development concept of innovation, coordination, green, openness and sharing, and strive to build the most dynamic and growing modern printing enterprise in China. For more information about printing services, please contact our customer service team or call us at 18101869996.

Our service program starts from understanding the needs of our customers, and then builds excellent services with elite talents and advanced management. Through digital publishing technology application services and digital content services, we provide customers with overall solutions such as mobile Internet applications, digital content technology services, and digital asset management. Based on cost, quality and speed are the personalized competitiveness of our enterprises, and the precise management model focusing on communication is the first priority to support our excellent service. We conduct an all-round analysis of the project, relying on excellent independent research and development and unremitting butler service, to become a one-stop service provider that you can rely on. Our professional customer service staff has been working with excellent industry experts to create professional and personalized solutions for customers.

Jinshi Packaging is a brand of Jinshi Packaging (Jiaxing) Co., Ltd. Since its establishment, Jinshi Packaging has always focused on the research and production of composite flexible packaging and container packaging, and insists on quality safety and scientific and technological innovation as the primary core competitiveness of enterprise development. At present, it has 5 specialized chemical plants in Jiaxing, Wenzhou and Tianjin (under construction) in China, with 1,100 employees and a total annual output of more than 35,000 tons. The company has introduced international and domestic leading production lines, such as Fuji FCD-11 color gravure printing machine, FL2 dry lamination machine, solvent-free lamination machine in Italy, curved printing machine in the Netherlands and Demag injection molding machine. It has a 100,000-level purification workshop that meets GMP standards, a modern technology research and development center and a product quality testing center, and has international advanced precision testing equipment, such as moisture permeability meters, oxygen permeability meters, infrared analyzers, and gas chromatographs imported from the United States. The company has successively won "Provincial Packaging Industry Model Enterprise", "Zhejiang Famous Trademark", "Zhejiang Famous Brand Product", "China's Top 50 Printing Enterprises", "China Dairy Packaging Service Excellent Enterprise Award", "China Packaging Excellent Brand", 2010\2011\2012 won "China's Top Ten Brands of Pharmaceutical Packaging Materials", "China's Pharmaceutical Packaging Industry Outstanding Contribution Unit", "Dairy Packaging Technology Innovation First Prize" and many other honors, and was recognized as "National High-tech Enterprise". At present, the company is a provincial patent demonstration unit, a provincial advanced scientific and technological enterprise, and a municipal R&D center, with more than 110 patented technologies, and works closely with many well-known domestic universities and scientific and technological institutions to strive for the leading level in the industry. National packaging industry leaders: Guangming, Yili, Mengniu, Yakult, Danone and other dairy products, Yunnan Baiyao, Beijing Tongrentang, Henan Lingrui and other drugs, Shanghai Jahwa, Sephora, L'Oréal and other daily chemicals strategic partners - Jinshi Packaging sincerely invites you to join!

Anhui Jinke Printing Co., Ltd. is a professional supplier of plastic color printing composite flexible packaging, providing packaging design, production, production and after-sales service for food, medicine, seeds, daily chemical products, etc., specializing in flexible packaging for more than 20 years, with 10,000-level purification workshop and advanced production and testing equipment, and obtained food QS production license, drug GMP certification qualification and import and export self-operation rights and other certificates. Relying on the efforts of Jinke people for many years, the company's strength, integrity, product quality and service have been recognized by the industry, and the company has won space for survival and development, and in 2010, a wholly-owned subsidiary, Anhui Jinke Pharmaceutical Packaging Materials Co., Ltd., was established. In 2012, it was rated as one of the top 100 in China's packaging industry, one of the top 40 in China's plastic packaging industry, and in 2015, it was awarded a well-known trademark in China, and was rated as a contract-abiding and trustworthy unit, a star enterprise, and a large taxpayer for consecutive years. The company's healthy and sustainable development is not only due to the corporate purpose of integrity, quality, responsibility, efficiency and win-win, but also thanks to long-term and stable partners, food packaging cooperative enterprises include: COFCO, Jiangsu Shangyi, Inner Mongolia Hengfeng, Xinliang Grain and Oil, etc., pharmaceutical packaging cooperative enterprises are: Beijing Tongrentang, Yunnan Baiyao, Yuekang Pharmaceutical, Anke Biotechnology, Chongqing Heping, Tianjin Hongri Pharmaceutical, etc., seed packaging includes Dunhuang Pioneer, Denghai Pioneer, Beijing Orijin Seed Industry, Longping Hi-Tech, Dabeinong, etc. The company mainly produces a variety of food packaging, pharmaceutical packaging, daily chemical product packaging, seed pesticide packaging composite bags and composite films, materials include BOPP, CPP, PET, PA, PE, aluminum foil composite, paper-plastic composite, etc., bag types are divided into stand-up bags, zipper bags, zipper bags, ziplock bags, vacuum bags, three-sided sealing bags, middle sealing bags, side sealing bags, four-side sealing bags, folded edge bags, eight-sided sealing bags, etc., anti-counterfeiting technology is aluminum plating hollowing, computer inkjet coding, laser, scratch ink, laser anti-counterfeiting, ink anti-counterfeiting, laser holographic anti-counterfeiting, etc.

Launched in 2009, Kam Shing has about 30 years of experience in the manufacture and sale of corrugated cardboard and paper packaging products. The product categories include printed corrugated boxes, corrugated cardboard, offset printing packaging products and manuals, etc. Jinsheng was rated as one of the top 500 enterprises in Shenzhen from 2018 to 2020, one of the top 100 printing enterprises in the People's Republic of China ("China") for 18 consecutive years from 2003 to 2020, and as a national outstanding foreign-invested enterprise for 15 consecutive years from 2006 to 2020. The Group has established long-term relationships with more than 250 local and overseas customers in industries such as electronic appliances, food and beverage, furniture, pharmaceuticals and audio-visual products, paper packaging, and other consumer goods. The production bases are located in Shenzhen, Huidong and Dongguan, with an annual production capacity of about 680 million square meters of corrugated cardboard and about 450 million pieces of paper packaging. The Group's long-term suppliers include Lee & Man Paper Limited and Nine Dragons Paper (Holdings) Limited. In terms of corrugated board production, the main ones are: a 2.5-meter fully automatic high-speed corrugated cardboard production line made in the United States that can produce A, B, C, E combination pit types, a 2.5-meter automatic high-speed corrugated cardboard production line made in China that can produce A, B, C, E combination pit types, a 1.8-meter automatic production line made in Taiwan that can produce A, B, C, E combination pit types, and a pit production line that can produce A, B, C, E pit types; In terms of flexographic printing corrugated box production, the main ones are: six-color/four-color/two-color flexographic fly printing machine; Among them, Dobeck TP200 six-color die-cutting groove ink printing machine, the number of printing lines can reach 110~130 lines, can directly convert offset printing to flexo printing, the effect is comparable to offset printing, once won the 2007 DuPont Best Offset Printing to Flexo Printing Award, but the cost is reduced by about 30%, the maximum size reaches 2200mm X 1260mm offset printing corrugated box production line, mainly including: six-color/five-color/two-color high-speed full-open/folio printing machine a total of 7 sets; Including German Heidelberg and Gaobao offshore printing production lines, the maximum size of 1640MM X 1205MM paper tray production lines mainly include: pulp molding hot press shaping machine. There are other post-processing equipment such as paper tray fixing machine, direct combustion fuel drying line and natural drying field, such as automatic oil polishing machine, automatic laminating machine, automatic die-cutting machine, manual beer machine, automatic nailing machine, hybrid folding machine, multi-head stapling machine, nail riding machine, etc. If there is no professional and efficient management team, even if it has advanced equipment, if you want to achieve the development goal of "domestic first-class enterprises and international well-known brands", it can only be on paper. Mr. Zhuang Jinzhou, the founder of the group, has continuously introduced high-quality management talents under the condition of breaking the management trend of the family business, and at the same time redesigned the group's human resources, performance system, compensation system with the help of "outer brain" --- professional management consulting company, and gradually established a scientific and standardized group management and control model. In terms of production and operation, it is the first in the industry to apply a tailor-made ERP enterprise resource planning system, which realizes the whole process of information control from procurement, order to logistics and finance, so that the process is informatized, management is transparent, and the result is data. In the development process of Jinsheng, the cultivation of talents is a crucial part, within the enterprise, the company has a special "hope engineering training room", according to the plan to implement the training of professional mentality, production technology, quality management, customer service, fire safety and other aspects of the employee, at the same time, linked with Shanxi University of Finance and Economics and other colleges and universities, to entrust the training of potential staff or management cadres and carry out talent exchanges. After more than 30 years of ups and downs, Jinsheng has grown from a workshop-style cardboard processing factory to a modern group company, and has become a packaging supplier for many famous brands, and we will continue to work with high-quality brand customers to build strategic partnerships.

Songyu Printing and Packaging Co., Ltd. is a comprehensive technical enterprise integrating printing and packaging technology research and development and product design, production and sales, established in August 2010, with a total plant area of 24,793.6 square meters. He is a standing member of industry associations such as the China Packaging Federation and the Printing Association, and has drafted a number of national and industry standards. In 2014, it passed the ISO9001/IS014001 dual system certification. At present, the company has two production bases in Hangzhou and Chengdu (under construction). With a high-level packaging R&D team and high-quality technical personnel, it has successively introduced Italian Serudi ten-color rotary gravure printing machine, Nordmec solvent-free compounding machine, all French DCM back-end processing equipment, and imported RTO facilities equipped with high-quality current treatment efficiency to ensure the safe operation of production. The company always adheres to the principle of "green, digital, creativity: for the development direction of the enterprise, explores new applications of digital printing and intelligent packaging technology, sets industry benchmarks and sets an example with core technology, and strives to become a leader in the technology-based, innovative and lean green printing and packaging industry with excellent technology and unlimited creativity." According to the development trend of green printing, research and implementation of green printing from design, material, process, waste treatment, the research direction includes green improvement and innovation of existing materials and processes, as well as the development and application of new environmental protection materials and processes, and strive to bring customers greener and safer product packaging solutions, with novel creativity and brilliant effects, to give products rich value and connotation.

Founded in 1994, Jiangsu Zhongcai Printing Co., Ltd. has developed into a printing enterprise covering an area of 180,000 square meters, a construction area of 100,000 square meters, fixed assets of 380 million yuan, and an annual production capacity of 1.6 billion yuan with a construction area of 180,000 square meters. The company has now developed into Jiangsu Zhongcai Printing Co., Ltd. as the core, and its subordinates are Sichuan Zhongfei Packaging Co., Ltd. and Jiacai Packaging (Danyang) Co., Ltd.; Overseas investment to establish the North Korean East Baek Joint Venture and the North Korean East Ming Cooperative; Introduce foreign capital and foreign cooperation to establish China-Hong Kong Packaging Products (Jiangsu) Co., Ltd., becoming a comprehensive group printing enterprise with domestic layout and overseas breakthroughs. The company has nearly 1,500 employees, including nearly 100 professional engineers and technicians, and the main production equipment includes: prepress equipment such as Akefa CTP system, screen electric extension, platform scanner, etc.; Gaobao offset printing machine (5 colors, 6 colors, 7 colors), Heidelberg offset printing machine (5 colors, 6 colors, 7 colors), Yajiafa 8-color flexo printing machine, 9-color paper rotary gravure printing machine, 10-color plastic rotary gravure printing machine, automatic screen printing machine and other printing equipment; Automatic partial varnishing machine, calendering machine, laminating machine, laminating machine, laminating machine, holographic hot stamping machine, embossing machine, die-cutting machine, folder gluer, hemming machine, bag making machine, binding machine and other post-press equipment; It has formed five major printing production lines with offset printing, paper concave, plastic concave, flexo printing and silk screen printing, mainly engaged in tobacco packaging, wine packaging, food packaging, gift packaging, social packaging, plastic packaging and other comprehensive packaging products. Since its establishment, the company has always adhered to the business philosophy of "customer focus, talent as the cornerstone, environmental protection as its own responsibility, full participation, development by quality, efficiency by management, and market competition by reputation", and the integrated policy of "integrity and law-abiding, excellence, pollution prevention, and continuous improvement". Focusing on internal management, reducing costs and benefits, and expanding the market, the company has shown a sustained, stable and healthy development trend, and won high social reputation and economic benefits. The company has now established lasting production partnerships with more than 50 foreign-funded and Sino-foreign joint ventures and has become the designated supplier of its packaging products.

Fujian Xiamen production base was established in January 2012 with a registered capital of 500 million yuan, a total investment of 2 billion yuan, a factory area of 360 acres, an annual production capacity of 40 billion pieces, Hubei Xiaogan production base was established in March 2022, a registered capital of 200 million yuan, a total investment of 1.2 billion yuan, a factory area of 264 acres, an annual production capacity of 30 billion pieces, the intelligent factory has the highest intelligent automation production line in the industry, equipped with 52 combination machines, 4 slitting lines, 3 wave tangent lines, 8 printing lines and 7 roll coating lines. Digital factory MES data-driven BI system realizes visual analysis, accelerates accurate decision-making, and improves management efficiency. Focusing on QMS, SRM\ERP\MES\CRM is integrated from source to terminal to form a closed-loop management mode. Won the 2023 "National Industrial Internet Pilot Demonstration" and "Fujian Province's New Generation Information Technology and Manufacturing Integration Development"

Shanghai Ailu Packaging Co., Ltd. (stock abbreviation: Shanghai Ailu, stock code: 301062) was established in 2006, mainly engaged in the research and development, design, production, sales and service of industrial paper packaging, plastic packaging and intelligent packaging systems. From "Made in China" to "Made in China" - after years of continuous development, the company has grown from a leading industrial paper packaging company in China to a provider of integrated solutions for both industrial and consumer packaging products. Since its establishment, the company has always ranked at the leading level in the industry in terms of production efficiency, large-volume order guarantee supply capacity, and product quality stability. The company's downstream market covers many fields such as chemical industry, building materials industry, food industry, food additive industry and pharmaceutical industry. Over the years, with a good market reputation and brand influence, Ailu has formed a stable cooperative relationship with leading enterprises in various fields, including Miaokolando, Mengniu, Guangming, Nestle, Friesland, Dow, BASF, Shenyang Chemical, Bailian, JCDecaux, Nippon, Oriental Yuhong, Meichao and other well-known industrial and consumer enterprises at home and abroad. Quality is the root, and the packaging of customer products is the most understandable - the company has a total of 68 patents authorized and still valid, including 17 invention patents and 51 utility model patents and design patents (as of the end of 2022). The company has successively passed ISO 9001:2015, ISO 14001:2015, ISO45001:2018, ISO22000:2018, BRCGS, HACCP, HALAL and other international management system certifications in the fields of quality, environment, occupational health and safety, and food safety. At the same time, the company has also obtained Sedex registration, ECOVADIS registration and other relevant qualifications to enter the international market. The company is a science and technology giant recognized by Shanghai, a municipal enterprise technology center, and a high-tech enterprise in Shanghai. The company's brand "Ailu Packaging" was rated as a famous trademark in Shanghai; The company's products kraft paper bags for food packaging have been recognized as Shanghai famous brand products; From 2018 to 2022, the company entered the list of "Top 100 Printing and Packaging Enterprises in China" selected by the industry's authoritative media "Printing Manager" magazine for five consecutive years; In 2021, the company was selected into the green manufacturing list of "National Green Factory" by the Ministry of Industry and Information Technology; In 2023, the company was awarded the title of "Shanghai Smart Factory".

| ChinaPictures of knife packaging boxescategory | ChinaPictures of knife packaging boxesQuotation (reference) |

|---|---|

| Zippered cardboard box | $2 – $7 |

| Acrylic display box | $15–40 |

| Zippered cotton and linen gift bag | $80–200 |

| Food grade plastic gift box | $12 – $30 |

| Transparent paper box with window | $30 – $80 |

| Transparent paper box with window | $4 – $10 |

| Environmentally friendly degradable cartons | $10 – $25 |

| Easy stainless steel gift tray | $120–300 |

| Heaven and Earth Cover Gift Set Box | $25–70 |

| Hot stamping cardboard gift box | $10–30 |

| Lacquered wooden gift box | $20 - $50 |

| Customized paper gift inner box | $12–35 |

| Round metal gift box | $50–120 |

| Environmentally friendly degradable cartons | $4 – $10 |

| Corrugated gift box | $15–40 |

The 2026 China excellent Pictures of knife packaging boxes printing vendors Top 10 ranking is complete. Featuring authentic reviews and comparison charts. Questions about the list or printing needs? Click to chat with our professional team for free tailored advice.

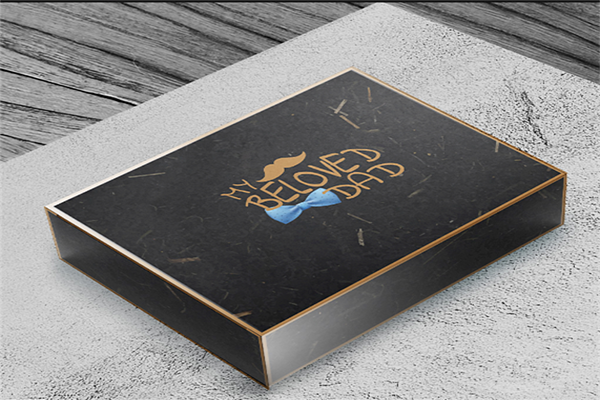

Meet the core needs of consumers, easy to pack, store, and open, and increase the attractiveness of products

Selected paper materials, lightweight, foldable, recyclable, environmentally friendly, and odorless

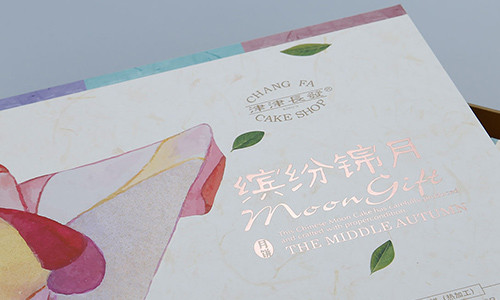

Match brand personality, align with product attributes, make the brand more recognizable, and create a charm from the outside in

Film coating UV、 Surface treatment processes such as hot stamping and pasting increase the high-end and exquisite quality of packaging boxes

Related Products

/ Relevant product

Related Products

/ Relevant product