Specializing in AA packaging color box printing in Shanghai, Rongli Printing factory delivers direct high-end customization with hot foil, UV coating, soft-touch, and specialty effects. Food-grade compliant materials with FSC certification, low-volume support, bulk savings, free design assistance, and fast production for standout results in luxury cosmetics and gift markets.

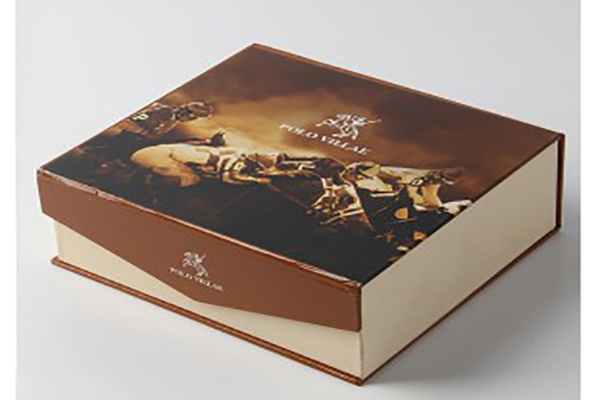

Based in Shanghai, we specialize in AA packaging color box printing, offering a complete one-stop service from design and free proofing to mass production. Equipped with German Heidelberg presses and Japanese premium inks, we combine 6+ processes like hot stamping, spot UV, embossing, and debossing—delivering vibrant colors, sturdy structures, and luxurious feel for cosmetics, food, gift, and pharmaceutical brands.

| Service Capability | Industry Standard | Our Performance |

|---|---|---|

| Processes per Box | 3-4 processes | 6+ complex processes combined |

| Proofing Speed | 3-5 days | Free digital proof same day |

| End-to-End Support | Segmented handling | Dedicated one-stop manager |

Our AA packaging color box printing solutions in Shanghai include full support for PVC/PET windows, custom foam/EVA inserts, blister trays, and divider cards. All elements are precisely integrated into the box structure to enhance product visibility and protection while maintaining premium appearance for cosmetics, electronics, and gourmet items.

| Feature Specification | Conventional Support | Included Options |

|---|---|---|

| Window Material & Shape | Basic square only | Custom shape PVC/PET windows |

| Internal Insert Types | Limited foam | EVA, blister, card dividers |

| Insert Fitting Precision | Loose fit | Perfect custom-fit integration |

We set the industry’s lowest entry barrier with a minimum order quantity of just 100 pieces, while delivering the same premium materials, processes, and quality control as large runs. This enables emerging brands, e-commerce sellers, and limited-edition launches to access high-end packaging without excessive upfront investment.

| Order Quantity | Standard Requirement | Our Policy |

|---|---|---|

| Minimum Order | 500-1000 pieces | 100 pieces only |

| Quality Consistency | Reduced for small runs | Identical to large production |

| Setup/Die Charge for Low MOQ | Full charge applied | No die fee for 100+ pcs |

We offer three scheduling tiers—Standard, Priority, and Emergency—allowing you to choose the perfect balance of speed and cost. Priority slots guarantee production start within 24 hours, while Emergency activates our dedicated rush lines for maximum urgency.

| Scheduling Tier | Standard Access | Our Options |

|---|---|---|

| Production Start Delay | 3-10 days queue | Immediate to 24 hours |

| Priority Slot Availability | Limited or charged | Multiple tiers included |

| Schedule Change Flexibility | Rigid | 48-hour adjustment window |

Even at low quantities, we offer complete customization freedom—unique sizes, custom die-cuts, special inserts, and multi-process finishes. This level of personalization is typically reserved for large orders elsewhere, giving smaller brands access to truly bespoke packaging.

| Customization Type | Standard Volume Required | Our Minimum |

|---|---|---|

| Custom Die-Cut Shapes | 1000+ pieces | Available from 100 pieces |

| Special Inserts & Fitments | 2000+ pieces | No minimum restriction |

| Multi-Finish Combinations | Bulk only | Full access at any quantity |

We excel in accurate Pantone and custom spot color reproduction using dedicated ink mixing stations and daily calibration. Complex brand colors, metallic inks, and fluorescent shades are matched with laboratory precision, ensuring your corporate identity is perfectly represented.

| Spot Color Item | Standard Accuracy | Our Accuracy |

|---|---|---|

| Pantone Matching Precision | ΔE ≤ 2.0 | ΔE ≤ 1.0 |

| Metallic Ink Reproduction | Approximate only | True metallic effect |

| Custom Color Development | Limited capability | In-house mixing lab |

All our processes support soy-based and vegetable inks, FSC-certified papers, and water-based coatings for reduced environmental impact. We maintain full premium quality and process capabilities while prioritizing sustainability for environmentally conscious brands.

| Eco Process | Standard Ink/Coating | Our Eco Option |

|---|---|---|

| Ink Type | Petroleum-based | Soy & vegetable inks |

| Coating Chemistry | Solvent-based | Water-based & biodegradable |

| Process Compatibility | Limited eco options | Full process range eco-friendly |

We subject packaging to extended vibration testing on shaker tables simulating truck, air, and sea transport. This ensures contents remain secure and undamaged during long-distance shipping, especially important for fragile cosmetics and glass products.

| Vibration Test | Standard Duration | Our Duration |

|---|---|---|

| Truck Simulation | 1-2 hours | 8+ hours continuous |

| Frequency Range | Limited band | Full 1-200Hz spectrum |

| Content Security | Basic hold | Zero movement guaranteed |

Through long-term partnerships with leading paper mills and strategic inventory management, we ensure consistent material availability and price stability even during market fluctuations. Brands benefit from reliable production scheduling without unexpected delays or cost increases.

| Supply Aspect | Standard Situation | Our Situation |

|---|---|---|

| Material Availability | Subject to shortages | Strategic stock guaranteed |

| Price Fluctuation Protection | Passed to client | Locked pricing available |

| Lead Time for Special Materials | 4-8 weeks | In-stock premium options |

Running multiple SKUs together reduces setup costs, material waste, and production time compared to separate orders. Clients achieve significant savings while maintaining individual design integrity and delivery synchronization for complex product ranges.

| Cost Benefit | Standard Separate Runs | Our Combined Run |

|---|---|---|

| Setup & Tooling Cost | Multiplied per SKU | Shared efficiency savings |

| Material Utilization | Higher waste | Optimized sheet planning |

| Overall Unit Economics | Premium pricing | Better value at scale |

Our Kaizen-inspired continuous improvement program tracks quality metrics, conducts regular audits, and implements employee suggestions. This ongoing evolution has driven steady improvement in yield rates and customer satisfaction scores year over year.

| Improvement Metric | Standard Progress | Our Progress |

|---|---|---|

| Annual Yield Improvement | 1-2% gain | Consistent 3-5% gains |

| Audit Frequency | Annual external | Monthly internal + quarterly external |

| Employee Suggestions Implemented | Low adoption | High implementation rate |

We craft velvet-lined rigid boxes with magnetic closures, ribbon pulls, and multi-level inserts for jewelry, watches, and high-value gifts. These presentation boxes transform ordinary items into memorable gifting experiences that enhance perceived value.

| Gift Feature | Standard Box | Our Box |

|---|---|---|

| Interior Lining | Paper only | Velvet & satin options |

| Multi-Level Insert | Single tray | Custom tiered compartments |

| Presentation Mechanism | Basic lid | Ribbon pull & magnetic reveal |

Real feedback from verified brand partners highlights our strengths in quality, delivery, and service. Clients praise the premium finish, reliable timelines, and collaborative approach that make working with us seamless and enjoyable.

| Testimonial Theme | Common Feedback | Client Quotes |

|---|---|---|

| Product Quality | Good | "Flawless premium finish" |

| Delivery Reliability | Reliable | "Always on time" |

| Team Support | Helpful | "Exceptional partnership" |

We clarify what is possible with box size, shape, material, finishing, and quantity to help you design within achievable parameters. Understanding these boundaries from the start prevents revisions and speeds up project approval.

| Customization Area | Standard Limit | Our Capability |

|---|---|---|

| Box Size Range | Restricted dimensions | Nearly unlimited |

| Finishing Combinations | Limited stacking | Full multi-process support |

| Quantity Flexibility | High MOQ | From 100 pieces |

Elevate your unboxing experience with matching branded accessories such as custom stickers, thank-you cards, seal labels, and protective wraps. All items can be produced with the same materials and finishes as your boxes for perfect brand consistency.

| Accessory Type | Standard Option | Our Option |

|---|---|---|

| Custom Stickers & Seals | Generic shapes | Die-cut & foil stamped |

| Thank-You Cards | Plain card | Premium textured stock |

| Protective Wraps | Tissue only | Branded tissue & sleeves |